Optimizing Vacuum Calibrators for PVC Pipe Production

Dekuma, a renowned PVC extrusion supplier, specializes in advanced manufacturing solutions for various types of PVC pipes. Their innovative equipment, including vacuum calibrators, plays a crucial role in ensuring high-quality production. This article explores the essential features of vacuum calibrators and their significance in the PVC pipe manufacturing process.

Key Features of Vacuum Calibrators

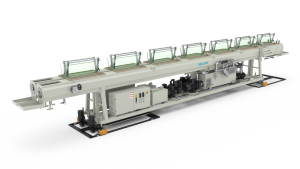

A vacuum calibrator is vital in the PVC extrusion process, particularly when producing PVC-U and PVC-M pipes. Dekuma’s optimized stainless steel vacuum calibration tank and piping enhance durability and effectiveness. The dual water cycle system, equipped with an independent filter, prevents nozzle blockages, ensuring a seamless operation. This feature is essential for maintaining consistent quality and performance in pvc pipe manufacturing machine supplier. Moreover, the quick-response vacuum control system guarantees a reliable vacuum level, crucial for achieving precise dimensions. High-efficiency spray cooling provides rapid sizing under vacuum conditions, which is particularly beneficial for maintaining product integrity during the cooling phase.

Applications of Dekuma’s Equipment

The series of double conical twin-screw extruders from Dekuma are specifically designed for producing various types of PVC pipe used in water supply, drainage, irrigation, ventilation, wire protection, industrial applications, and gas transportation. These machines work seamlessly with vacuum calibrators, ensuring high-quality, dimensionally accurate products. Both single-chamber and double-chamber vacuum calibrators are available according to product requirements, allowing manufacturers to customize their setups for optimal performance.

Conclusion

In summary, investing in high-quality vacuum calibrators is essential for any pvc pipe manufacturing machine supplier. Dekuma stands out as a leading PVC extrusion supplier, providing innovative solutions that enhance efficiency and product quality. With advanced features like optimized stainless steel construction and automatic controls, Dekuma’s equipment ensures that manufacturers can meet the demands of various applications while maintaining high standards of performance.